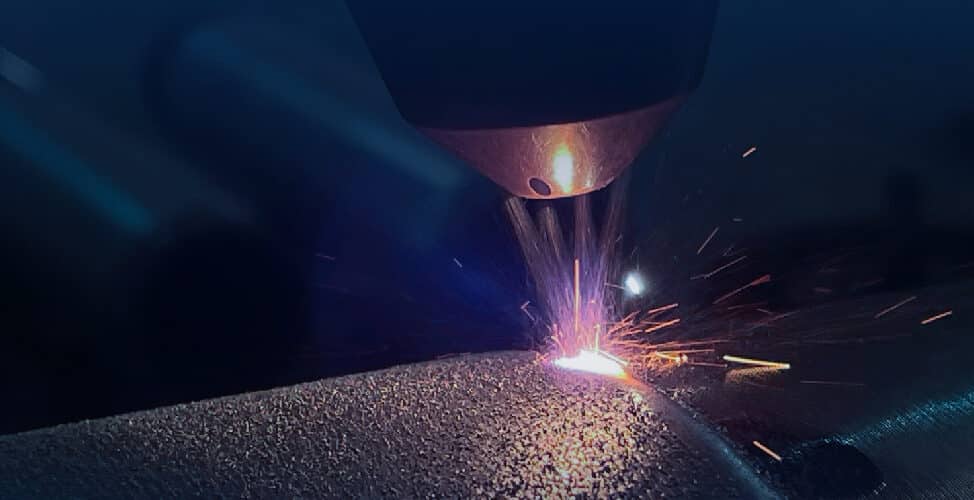

Laser welding is a high-efficient and precise processing pattern using high-density laser beam as its heat source. It is critical to the wide application of laser technology. Now, the application fields of laser welding has increasingly expanded its applicable fields, including manufacturing, powder metallurgy, automotive production, electronics, biomedicine and other fields aiming at BT20 titanium alloy, HE130 alloy and Li-ion battery.

When it comes to main characteristics, the welded workpiece has small deformation, with almost no connecting gap but high welding depth/width ratio. In this way, its welding quality will be better than that of other traditional patterns. Nevertheless, in order to get stable laser welding quality, it is required to keep a watchful eye on how to monitor the whole welding process and take control of its quality. Specifically, laser welding usually works with inductive, capacitive, sonic or photoelectric sensor, and electronic computers to track weld seams, detect welding defects and monitor weld seam quality according to different work requirements, after that, take feedback control and adjust technical parameters to automate laser welding. For laser welding, focal position of laser beam is one of the most critical parameters. Under certain laser power and welding speed, penetration depth will be maximized and weld shape will be made possible when the focus is within the optimal range. In practice, in order to avoid and reduce factors that affect the stability of the focal position, professional clamping tools and technology are in need, which are complementary to the actual quality of laser welding.

In comparison with other traditional welding patterns, laser welding has advantages below:

1.Fast speed, high depth and small deformation.

2.Welding can be performed at room temperature or under special conditions, and welding devices are simple. At this request, laser beam doesn’t shift while passing through electromagnetic field; laser welding can adapt to environments containing vacuum, air and other certain gases; laser can penetrate through glass or other transparent materials relative to laser beam.

3.Titanium, quartz and other refractory materials, as well as heterogeneous stuff can also be handled at high quality.

4.In view of high laser density after laser focusing, the depth-to-width ratio can reach 5:1, or 10:1 at most at high laser power.

5. Micro welding is also achievable. After focusing, laser beam will generate a small laser spot and be positioned, which fits to make assembly welding for micro and small workpieces during automated production in batch.

6. Due to contactless and long-distance work, it can weld inaccessible parts and work flexibly. Because of optical fiber transmission used in YAG laser welding in recent years, laser welding has become increasingly promoted and applied.

7. It is possible to carry out multi-beam and multi-station welding thanks to its laser beam separated by time and space. In this way, you can realize high-precision welding.

But, laser welding is less than perfect:

1. It has high requirements on assembly accuracy of welded parts, and ensures that laser beam has no obvious offset on workpiece. The reason is that spot size is small and weld seam is narrow after laser focusing, therefore, if workpiece assembly accuracy or beam positioning accuracy fails to meet related requirements, it is easy to cause welding defects.

2. Laser generator and related systems are high-cost, needing relatively high early investment.