At present, the service environment of mining machinery is harsh. According to relevant statistics, about 1/3 to 1/2 of the world’s energy is consumed by friction. The wear failures caused by friction account for 70%-80% of the equipment damage, and the annual loss is more than 100 billion dollars. In addition, mining machinery is characterized by a large volume, high price, difficult loading and unloading, and a large amount of maintenance and repair work. Therefore, when the equipment stops running due to wear and tear, it will cause huge economic losses. In the past, the traditional coating process was electroplating hard chromium, which had a long processing cycle, serious environmental pollution, poor corrosion resistance, and can not guarantee the maintenance effect and huge potential production risks.

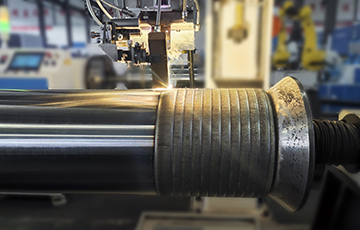

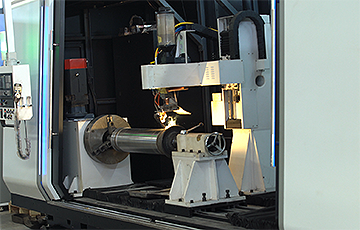

Laser cladding is a new technology with high economic benefits. It uses a high-energy laser as heat source, and the laser and alloy powder act synchronously on the metal surface to melt rapidly and form a dense coating, which can be used for coal mine mechanical parts after wear. It can be used for repairing the worn parts of coal mining machinery and enhancing the wear and corrosion resistance of the parts. This technology can remanufacture the failed parts in coal shearers and road-header picks, stainless steel columns of fully mechanized mining hydraulic supports, scraper machines, and gear transmission boxes. Especially, the laser strengthened coating of metallurgical combination, hard point, and the high-toughness metal material composite has been prepared at the end cone of the pick and the easily worn part of the hydraulic rod, which greatly improves its average service life.