Iron and steel enterprises use a large number of load-bearing equipment with high load, low speed, high precision, and high alloy in the process of processing and production. Some parts are prone to corrosion, wear, failure and scrapping during use.

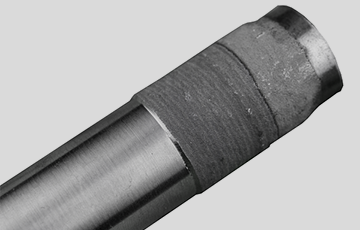

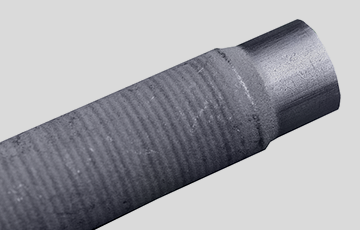

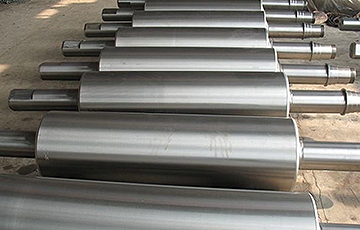

Laser cladding can be applied to many aspects in the metallurgical industry, such as laser strengthening and remanufacturing of hot rolls, rolling mill drive shafts, blast furnace tuyere nozzles, pinch rolls, conveyor rolls, tension rolls, flying shears, and large circular saws. The start-up and shutdown of the iron and steel industry is very easy to cause wear and tear on the equipment under the impact and friction of high-strength steel plates. However, the previous on-site surfacing repair can only play a temporary repair role, and cannot fully restore and extend the service life of equipment components. Spare parts of equipment through laser cladding can restore the spare parts to the best state and can restore the size of the worn part of the damaged or even scrapped parts for multi-cycle recycling. The repaired substrate can recover to the best state and ensure hardness and wear resistance. Due to the high fineness of the laser cladding powder, the repaired surface is also very perfect.